Customer case study

Van Gog Kwekerijen

100%

100%

20-50%

100%

Quality assurance and labour savings with EasyX

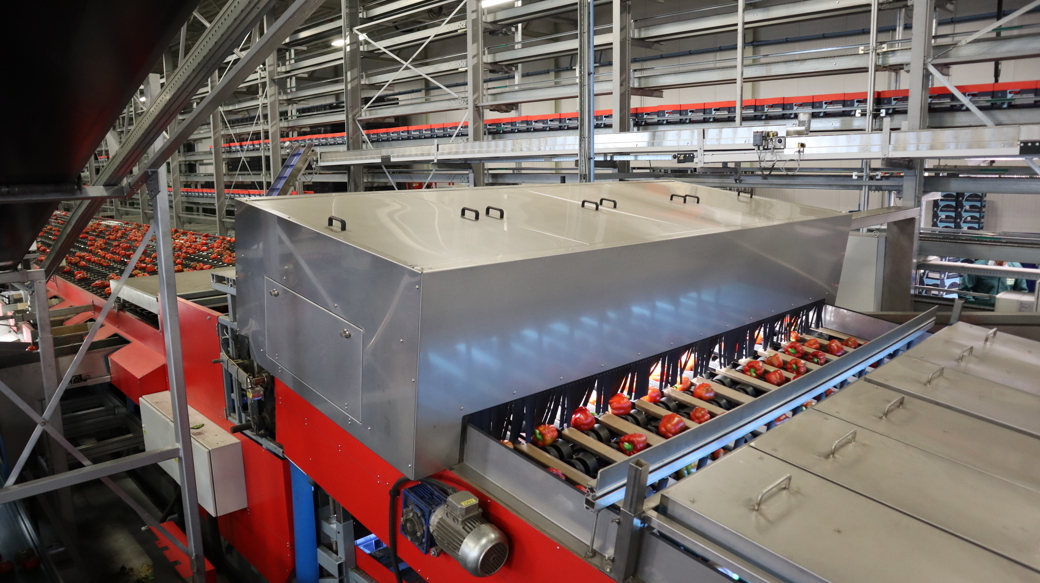

Van Gog kwekerijen (formerly Wijnen Square Crops) in Grubbenvorst invested in an EasyX for its existing sorting line to guarantee quality and save labour. Operations manager Charles Stax sees major advantages. "We can deliver consistent quality with significantly fewer people."

A few years ago, Van Gog kwekerijen expanded from 32 to 40 hectares of bell peppers, an increase of 25 per cent. We want to run at continuous capacity, says Stax. "Previously, we had 6 to 12 employees working on the sorting belt; now we no longer need people there. On average, 300,000 to 550,000 kg of bell peppers pass through the sorting line here every week, and those processes have to run optimally."

The EasyX photographs every bell pepper on the conveyor belt: it detects every deviation on the fruit. The human eye cannot compete with that, he says. "What's more, it generates a huge amount of data, which we can use to improve quality."

Quote

Previously, we had 6 to 12 employees working on the sorting belt; now we no longer need people there. On average, 300,000 to 550,000 kg of bell peppers pass through the sorting line here every week, and those processes must run optimally.

Save on sorting hours

The Limburg bell pepper grower is affiliated with Harvest House. There, the company's management heard promising things about the system used by fellow grower Vijverberg. The experiences with the EasyX are positive, according to Stax. "We are saving considerably on the total number of sorting hours. This is mainly due to the fact that we no longer need people on the sorting belt; the bell peppers are now automatically assessed for quality."

The system takes multiple photos of the bell pepper. "Based on these, you can select deviations that you want to classify as a second grade, such as shape, bruises or knife cuts," he continues. "The camera can even see the smallest scratch on the fruit. You have to learn to work with this by specifying the limits of what is and is not acceptable."

Damage caused by actions

In addition to quality benefits and labour savings, EasyX also generates a lot of data that can be used in other ways within the organisation. Suppose that a particular batch of bell peppers shows a lot of handling damage, such as bruises or cuts, Stax gives as an example. "The data now allows you to see exactly who harvested the bell peppers. You can talk to that person and work together to see how things can be improved, in order to raise the quality to an even higher level."

Van Gog Kwekerijen constantly strive to deliver a high-quality product. The growers at Harvest House want to grow high-quality fruit vegetables and must therefore comply with the cooperative's quality requirements, according to Stax. Bell peppers that do not meet the requirements are sold as second-grade produce, for example to cutting plants. These bell peppers are selected by the EasyX on the sorting belt and kept separate. "We have a market for almost all bell peppers," says the operations manager.

Another advantage of the system is that pests can be detected at an early stage. Stax: "The camera immediately detects if there is a small spot of aphids, spider mites or thrips on the fruit. Using this data, we can determine in which section those bell peppers were harvested, so that we can intervene more quickly to combat the pest."

Sorting reports

Charles Stax is pleased with the collaboration with Gearbox. The grower received an explanation of the EasyX on site and a number of items that were not standard in the programme have been adjusted, he says. "Improvements to the system are constantly being made. If we encounter any issues, we receive immediate assistance. Because EasyX generates so much data, we wanted to have a sorting report per greenhouse, per day, per week. That wasn't available yet, so they got to work on it right away. We also encountered deviations that were not yet included in the system. We are continuously working together to optimise the system."