What was once a manual and time-consuming process is now transforming into a streamlined, data-driven quality assessment thanks to GearStation, Gearbox's AI-driven vision solution. GearStation provides 100% in-line quality inspection of work delivered by humans, transporters or machines.

The future of the floriculture sector is smart, automated and intelligent.

Capacity increase of 12,000 flowers per hour with consistent quality

100% objective assessment thanks to AI vision

Immediate data insights for further optimisation

Less manual labour, fewer claims, more peace and quiet in the barn

90 per cent

30 +

75–100%

<3 years

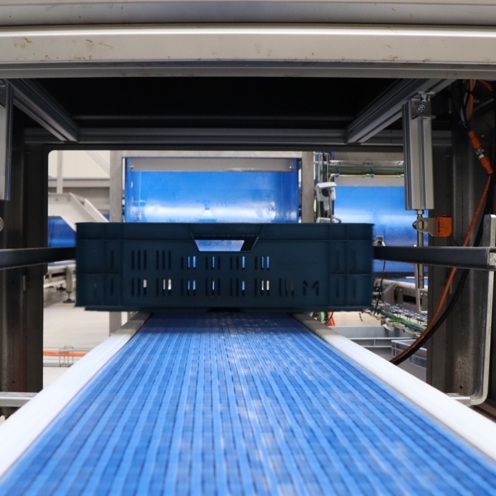

How the GearStation works

Our GearCore software platform assesses whether the product meets the necessary quality standards. Both vision and AI techniques are used for this purpose. You determine the quality standard for this assessment yourself via the user-friendly control interface. Each quality characteristic can be set separately. This prevents the wrong product from ending up with your customer.

-

Sort by: damage, discolouration, shape deviation, diameter and stem length

-

Quality assessment: counts per bundle, real-time processing and greenhouse data, improved uniformity of bundles, precise output control

-

Labour savings for quality assessment through smart cameras and AI.

-

Real-time data and reports for better decisions on labour, cultivation and claims

Real-time data and reports

The comprehensive reporting dashboard allows real-time monitoring of quality per phenomenon, batch and supplier. This provides factual and objective input for training and improving employees, assessing suppliers, and early detection of diseases and pests.

These growers, among others, rely on our solutions

Media

Our solutions work together with, among others:

Applications of the GearStation

Gerbera

The GearStation Gerbera is an integration on an existing bunching machine. The solution focuses on the complete digitisation and automation of quality assessment within the gerbera processing process.

Advantages of the GearStation for gerberators

-

Capacity increase of 12,000 flowers per hour with consistent quality

-

100% objective assessment thanks to AI Vision

-

Immediate data insights for further optimisation

-

Less manual labour, fewer claims, more peace and quiet in the barn.

Rose

Quality assessment is guaranteed with the GearStation Rose. This enables rose growers to offer higher quality to their customers. Growers save on labour costs and can offer their customers higher quality. Our technology is used daily by rose growers. This offers the following advantages, among others:

-

100% labour savings(higher capacity of roses per hour, less training time)

-

100% consistent in-line quality control

-

Real-time insight into data (quality, pests and damage, harvest, greenhouse staff, customers)

-

Fewer Claims ( sales per customer profile)

Vision and AI provide relevant data

All collected data is processed in real time and presented in clear dashboards. This not only gives companies insight into the current quality of their products, but also into broader trends, for example per employee, per greenhouse, per supplier or per season.

This data-driven approach enables continuous improvement of processes: employees can be trained in a more targeted manner, suppliers can be managed more effectively, and quality criteria can be tailored more accurately to market demand.